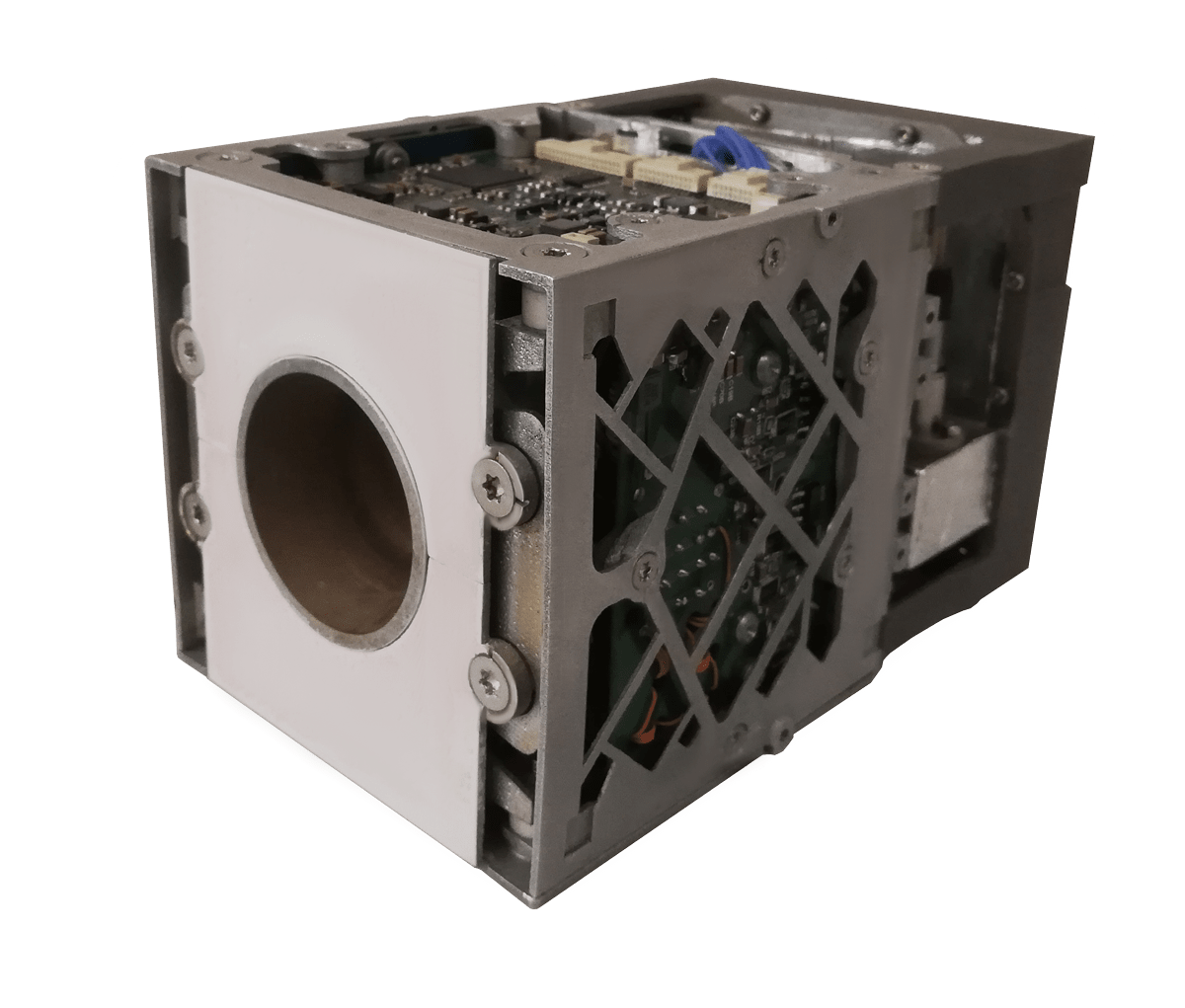

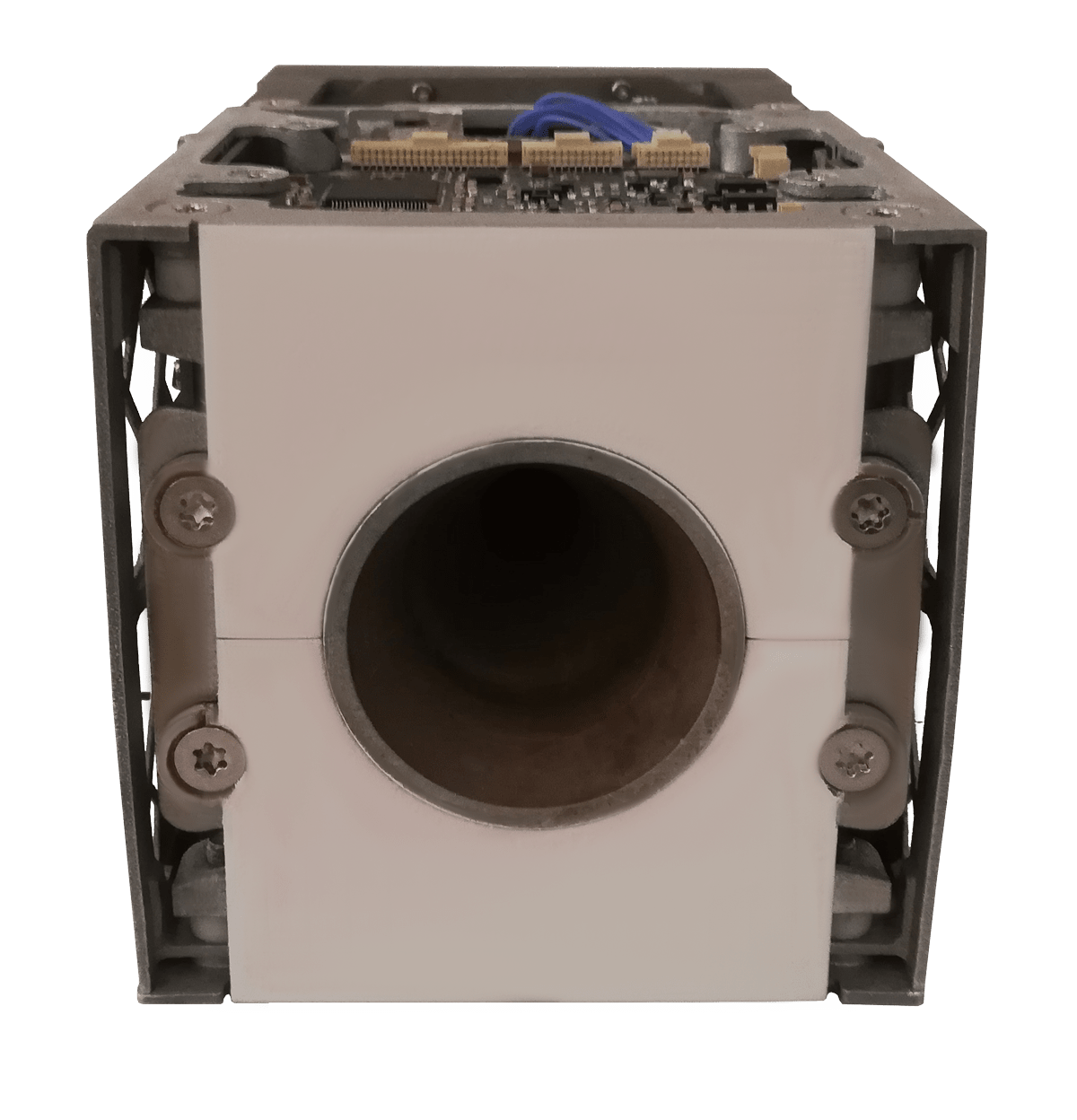

ELECTRIC PROPULSION SYSTEM

REGULUS-50-I2

A robust, versatile, and cost-effective propulsion system using iodine propellant

for smallsats and nanosat deployers.

APPLICATIONS

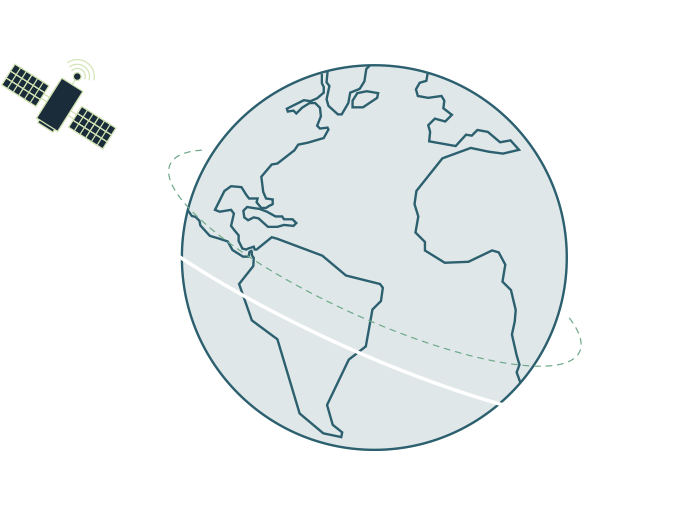

REGULUS-50-I2 enables new mission scenarios and efficiently makes in-track maneuvers possible, compensates drag in VLEO and performs end-of-life operations.

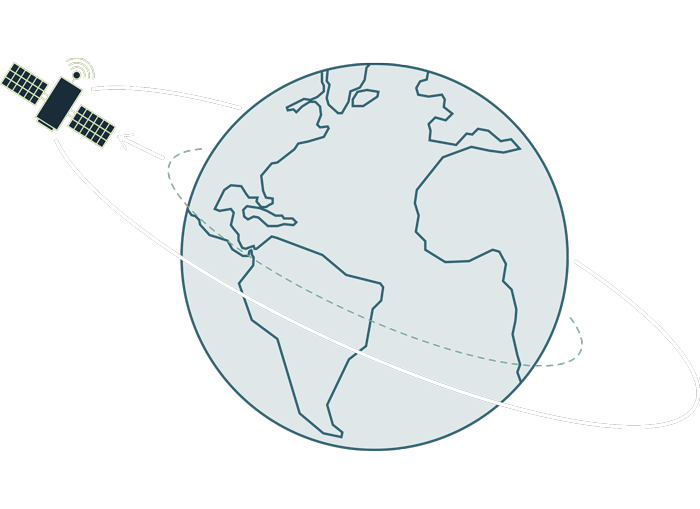

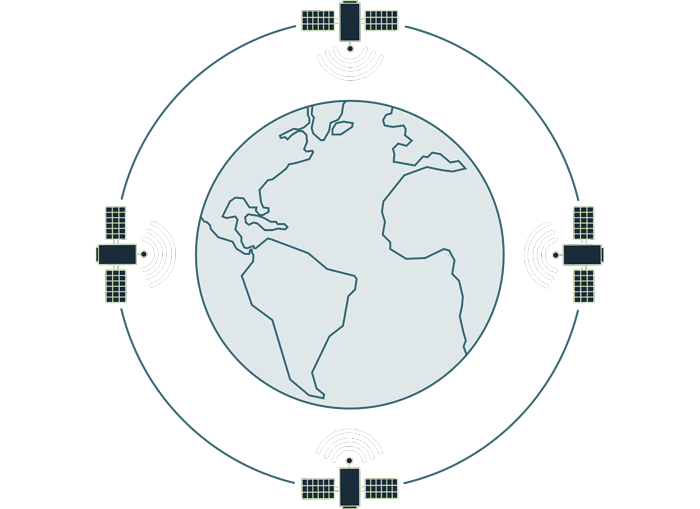

CONTINUOUS DRAG COMPENSATION

ALTITUDE CHANGES

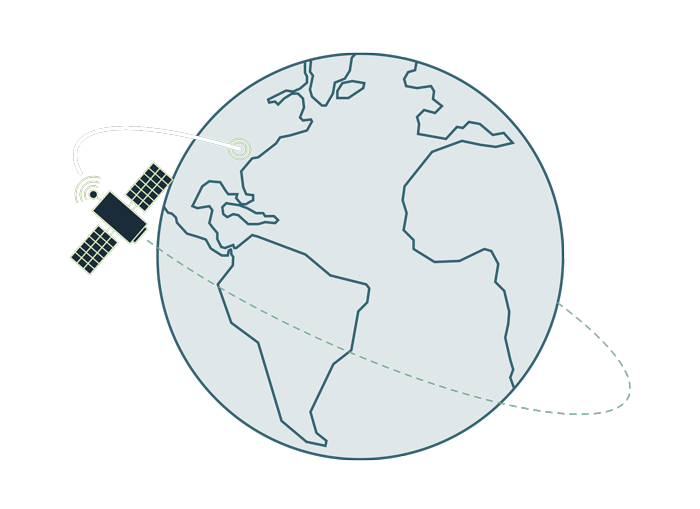

DECOMMISSIONING

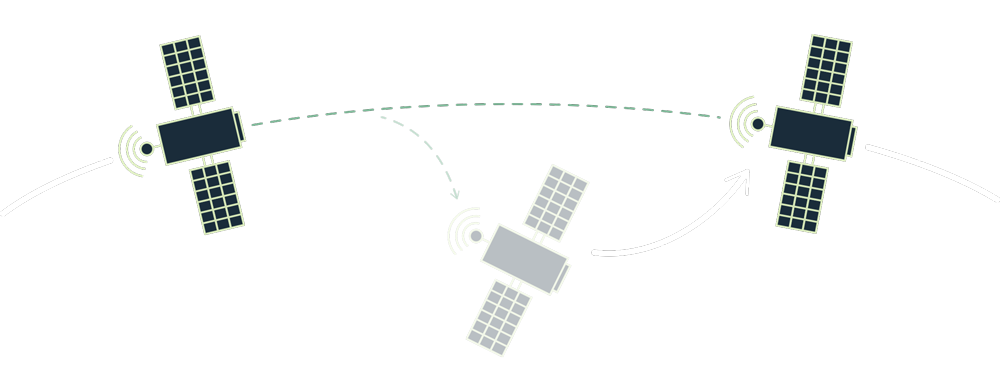

PHASING

STATION KEEPING

DE-ORBITING

SMALL

3000 Ns

MEDIUM

7000 Ns

LARGE

11000 Ns

MAIN FEATURES

| Thrust | 0.25 – 0.65 mN (highly modulable, 0.55 mN @ 50 W) |

| Specific Impulse | Up to 650 s (550 s @ 50 W) |

| Input power | 30 – 60 W (50 W nominal) |

| Mass flow | 0.1 mg/s |

| Volume | 93.8 x 95.0 x 151.0 mm referred to a Total Impulse of 3000 Ns |

| Weight | 2.5 kg @ 3000 Ns |

| Electric Interface | 12 V DC regulated |

| Communications | Can-bus or I2C with CSP protocol |