TECHNOLOGY

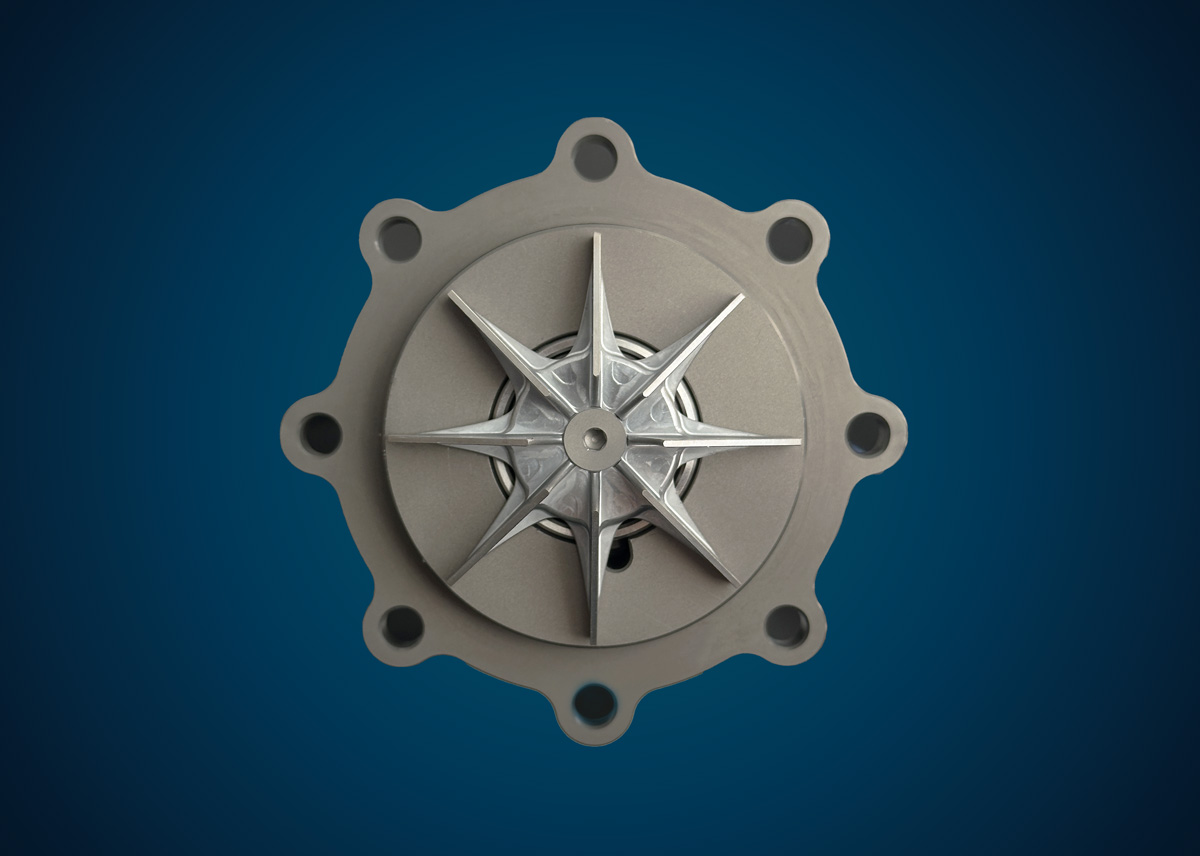

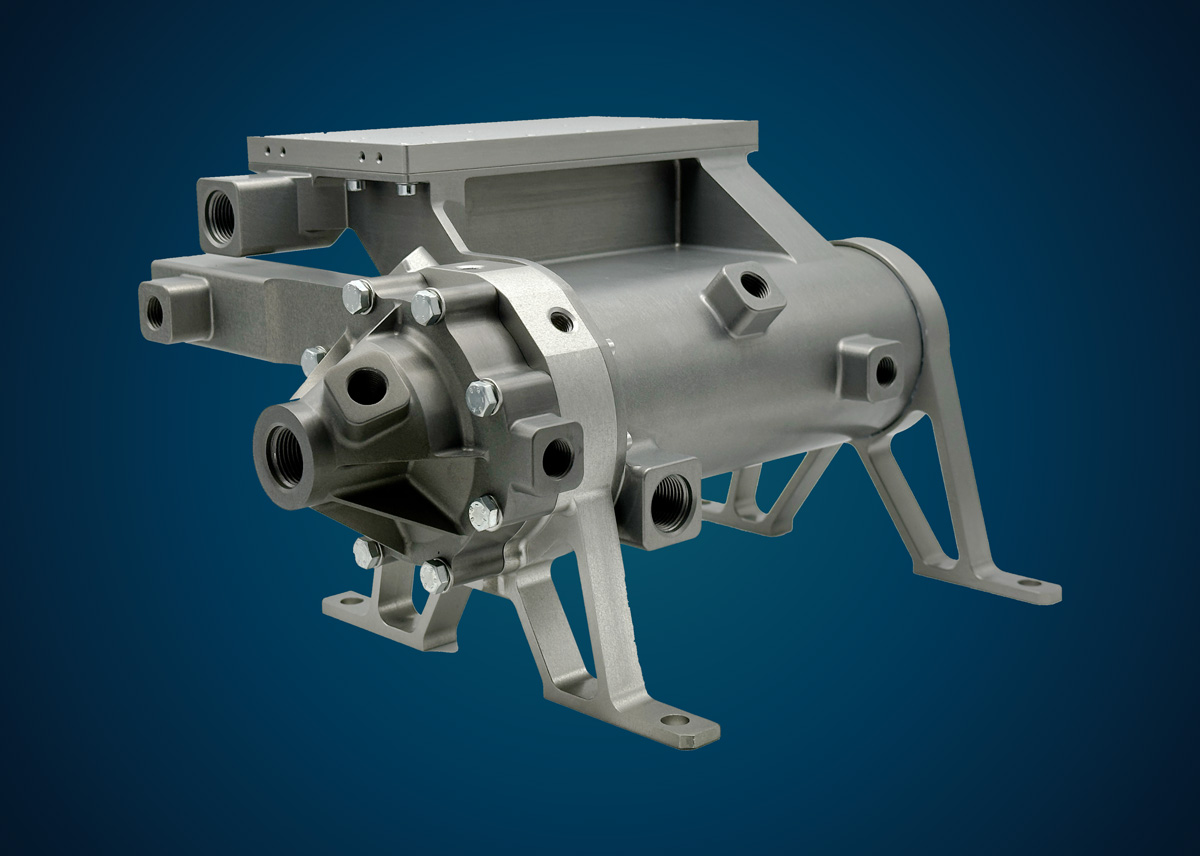

Electric Pumps

High-performance electric pumps for space applications: precise control, mechanical simplicity, and integrated cooling.

From design to prototype in 6 months.

UNMATCHED

CONTROLLABILITY

HIGH

PERFORMANCE

AFFORDABLE

PRODUCTION

TECHNOLOGY ADVANTAGES

Our electric pumps combine precision control, reliability, and ease of integration.

They are designed to give full authority over flow and system dynamics, without the compromises of traditional gas-generator cycles.

UNMATCHED CONTROLLABILITY

Fine throttling capability with a wide range of operations and efficient modulation of flow, precise regulation even at low mass flow rates, including multiple start/stop/restart and repeated operations without performance degradation.

COST-EFFECTIVE

Engineered to remain affordable for prototypes as well as low-volume production thanks to mechanical simplicity, compact design, fewer moving parts, no hot spots or extreme temperatures.

SELF-DIAGNOSTIC AND FAIL-SAFE

Built-in monitoring and automatic protection logic avoid catastrophic failures.

INTEGRATED COOLING

Co-designed cooling system for both pump and electronics keep internal components at moderate temperatures even in space environment with minimal heat transfer to interface elements.

HIGHER OVERALL PROPULSION EFFICIENCY

No exhausts and Isp losses typical of gas generator cycles and lower pressure budget and complexity respect to staged combustion cycles.

UPGRADEABLE

Software updates and the potential for further performance increases as higher-energy/power-density batteries become available.

SERVICES

We support the full lifecycle: custom design, system integration, acceptance testing, clean-room assembly, and qualification documentation. Our pumps are developed in close collaboration with integrators and prime contractors to fit mission-specific requirements.

TIMELINE

DEVELOPMENT

2019

Hot-fire test with pump-fed system developed with Thales Alenia Space Italia: 300 N HTP–kerosene combustion chamber. First studies on pump–combustion chamber interaction and pressure oscillations.

2022

Development of a partial-emission pump in collaboration with Thales Alenia Space Italia.