TECHNOLOGY

Chemical

Propulsion

We develop monopropellant, bi-propellant and hybrid propellant hydrogen-peroxide propulsion systems for in-space and access-to-space applications for small satellite platforms.

GREEN

PROPELLANTS

H202

HTP HIGHLY STABILIZED

1 N TO 10 KN

RANGE OF THRUST

Products under development

ALPHARD

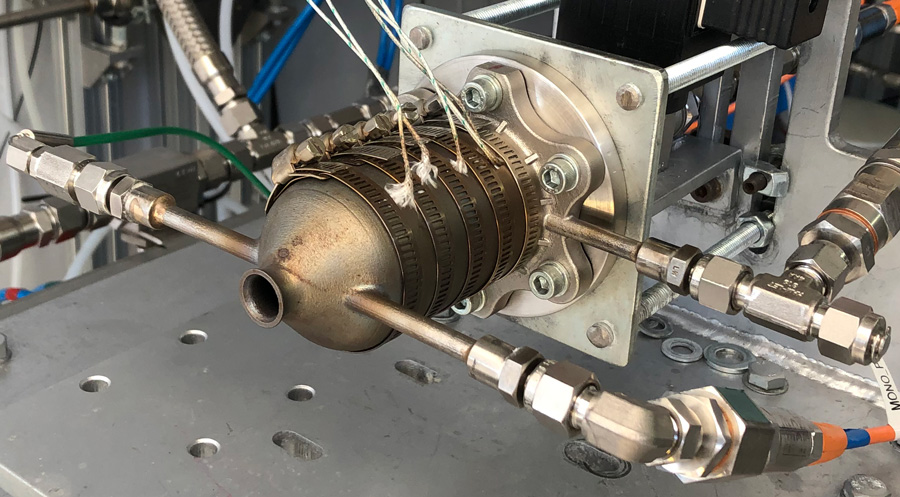

MONO

PROPELLANT

SYSTEMS

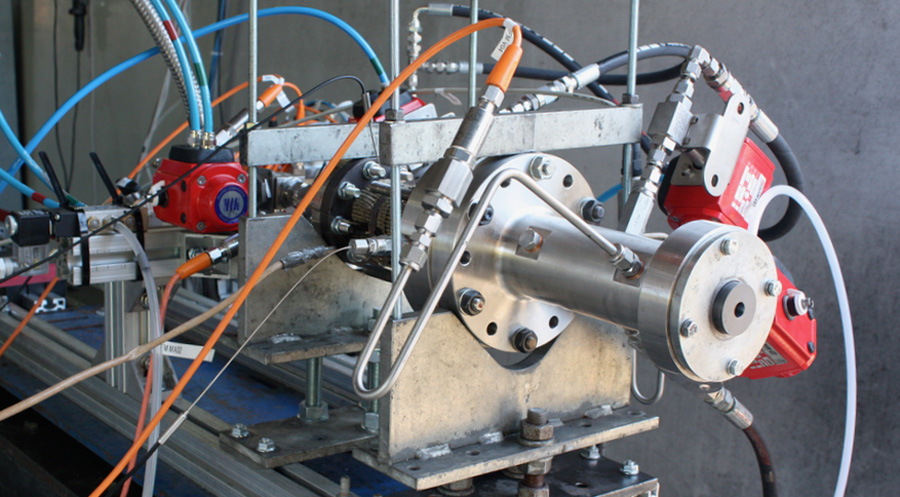

KUMA

BI-

PROPELLANT

SYSTEMS

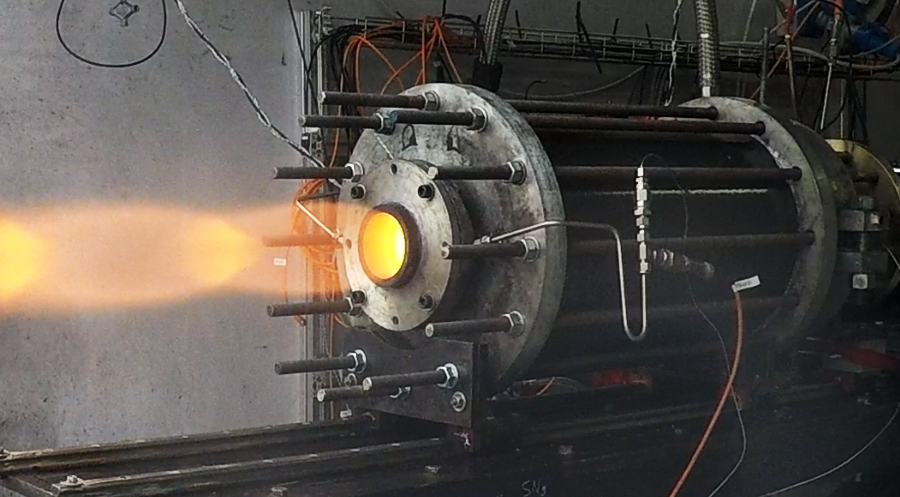

TEIDE

HYBRID

PROPELLANT

SYSTEMS

OXIDIZER

Our key technology for the oxidizer is highly-stabilized hydrogen peroxide, that is a green and non-toxic propellant.

We perform in-house concentration of our hydrogen peroxide, thus eliminating the transportation issues of highly concentrated H2O2 and allowing us to operate with a concentration level up to 95%.

In addition, we have an extensive expertise operating with nitrous oxide and gaseous oxygen.

FUEL

We use paraffin wax for our hybrid propulsion systems. Paraffin wax is a green fuel. In combination with H2O2 as oxidizer, exhaust gases are water, steam and CO2. Thanks to its liquefying characteristic, it provides high regression rates, thus allowing simple single port fuel grains. Our paraffin has thermomechanical performance able to withstand launch vibrations and in-orbit temperature stresses. We can use also polyethylene and polyethylene/paraffine blends depending on customers’ request and on mission specifications.

For our bi-propellant propulsion systems we use kerosene as green propellant.

MAIN FEATURES

depending on customer needs.

| Toxicity | All the combinations are green, non-toxic and non-carcinogenic, providing minimum environmental impact |

| Safety | High |

| Concentration | 90-95%. Tailored to customer requirements |

| Handling | Standard chemical protection suits, no SCAPE suits |

| Throttleability | 1:10 |

| Restartability | Yes |

capabilities

We carry out research and development activities

through a extensive combined numerical-experimental investigations

TIMELINE

FUNDED PROJECTS

We are developing chemical rocket motors since 2006.

The research and development took place through different research programs, both financed internally and within FP7/H2020 programs in cooperation with major Aerospace companies.